Operational Advantages

Ashoka has a wide range of machines from 50 T to 250 T.

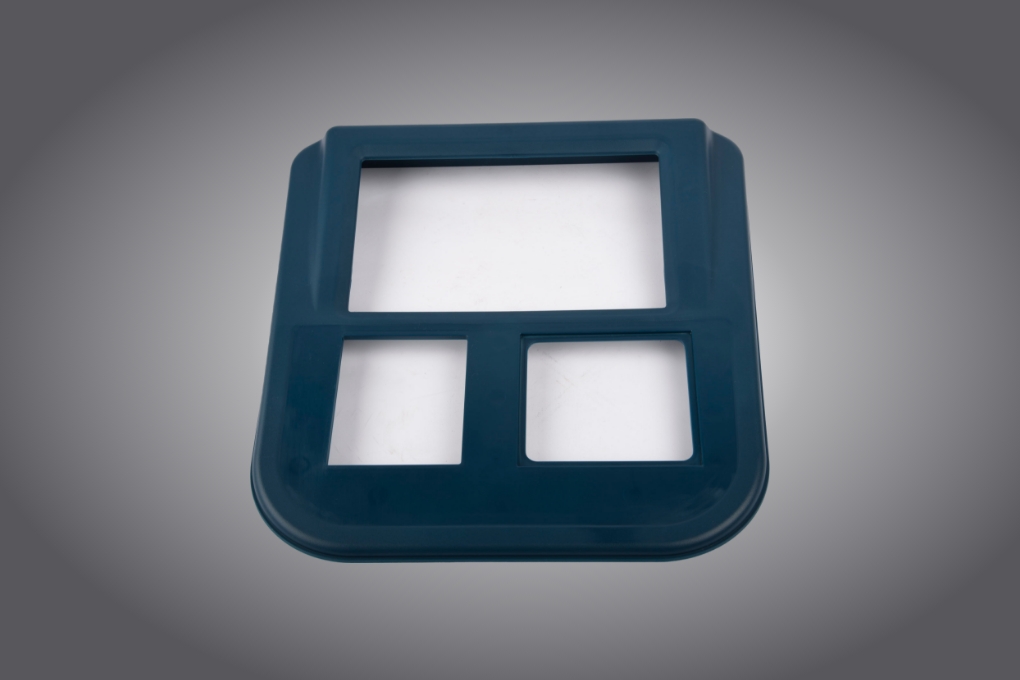

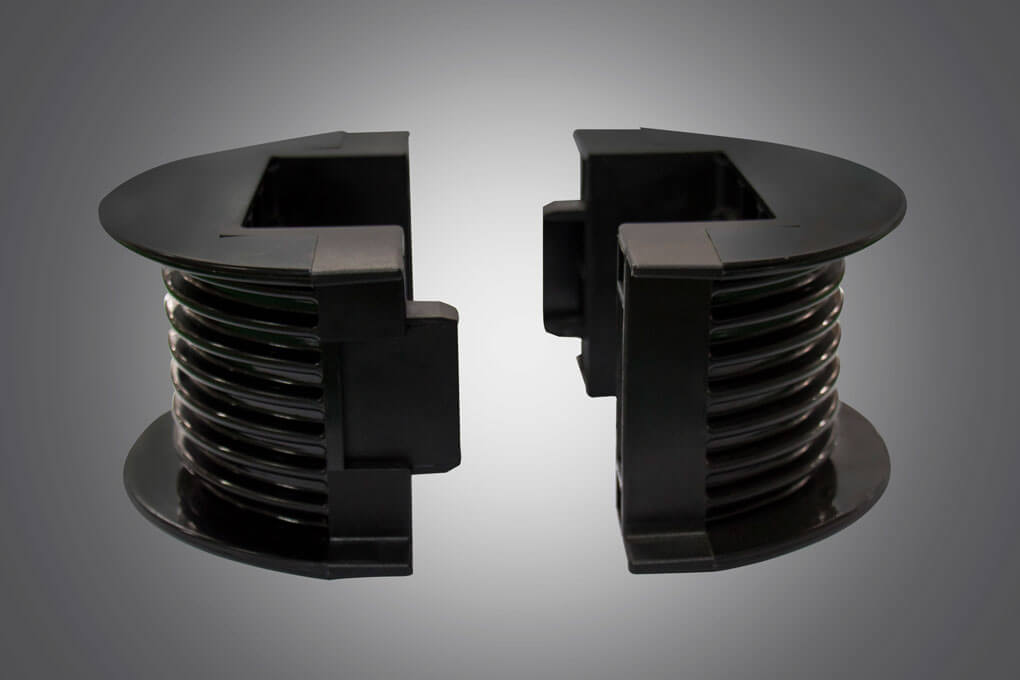

Specialized in Insert moulding.

Value added post moulding processes such as pad printing, heat transfer printing, machining, and assembling.

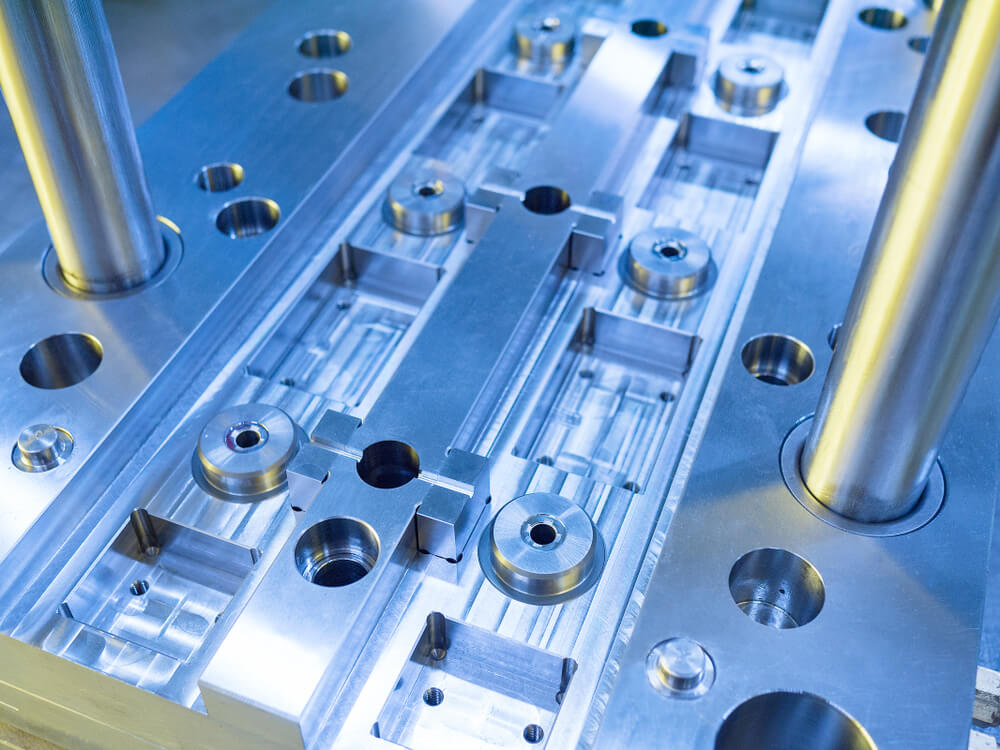

In house tool room to manufacture and maintain moulds.

Machines are operated and maintained for high productivity

Ability to process a large variety of materials.

Materials Utilized in Plastic Moulded Components

Affordable resin with high impact resistance, which is suitable for the production of plastic food containers.

Common group of thermoplastics that include High-Density Polyethylene(HDPE) and Low-Density Polyethylene (LDPE).

Low-cost, highly resistant thermoplastic that is suitable for the production of handheld consumer devices.

Tough, strong, super-stiff, heat-resistant polymers that are used for a wide range of industrial applications.

Insulation resistant polymer with high dielectric strength, strong dimensional stability and oil resistance.

Engineering thermoplastic with mechanical properties, and high chemical and abrasion resistance.